When replacing the ECM, the vehicle data must be written into the new ECM. The scan tool used for the replacement procedure must be the same from start to finish. If the scan tool is changed midway, information cannot be written correctly. So this instruction show you guide on how to reset/upload ECM data for ISUZU 2020 4JJ3 AWR6B45 truck.

Use the following procedure when replacing or programming the ECM.

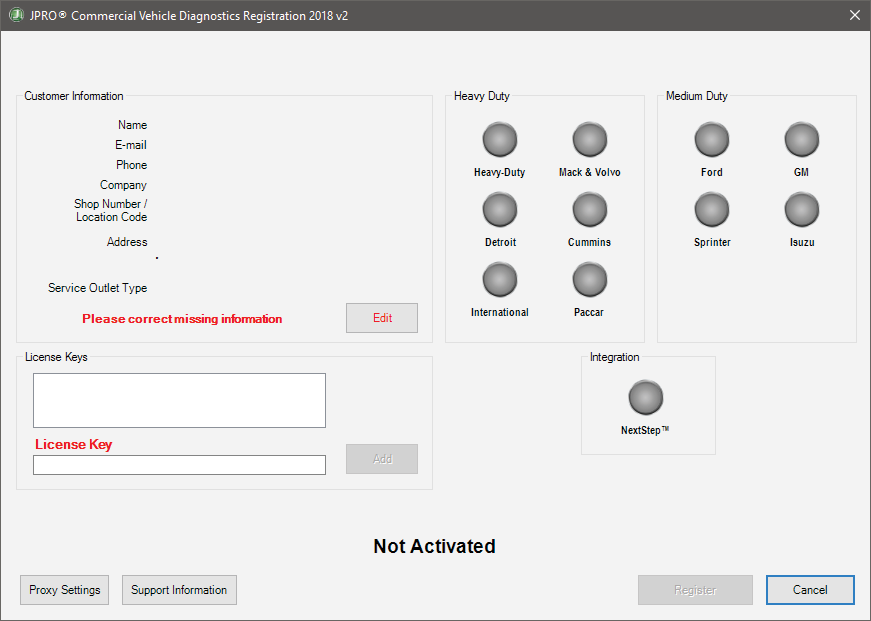

Preparations:

Isuzu G-IDSS Export Diagnostic Software Free Download

ISUZU N-Series Fuel Injector Flow Rate Programming by IDSS

Note:

*1: If reusing the ECM in another vehicle, perform the ECM reset in the original vehicle.

*2: Perform only for models with immobilizer.

Caution:

Because “ECM reset” cannot be performed in a new vehicle, be sure to perform “ECM reset” in the original vehicle.

1.ECM Reset

Caution:

When installing the ECM to the vehicle, it must be security linked to the wireless access module using the programming procedure. Once this linking has been performed, the ECM cannot be installed to any other vehicle. Before transferring (switching) to the vehicle in which the complaint originated, the resetting procedure must be performed in the original vehicle and the security linkages between each module must be reset.

If the ECM to be replaced cannot establish communication with the scan tool, do not perform this operation.

1) Connect the scan tool to the DLC.

2) Turn ON the ignition switch.

3) Select the scan tool item.

Diagnostics > Body > WAM (Wireless Access Module) > Special Function > Engine Control Module > Reset Engine Control Module

4) Erase the immobilizer information of the ECM by following the on-screen instructions.

Caution:

Entering an incorrect security code causes a security wait time.

Note:

When turning the ignition switch ON and OFF by following the on-screen instructions, wait at least 5 seconds before turning it OFF or ON each time.

5) Turn OFF the ignition switch for 30 seconds.

6) Verify that the engine does not start with all the keys.

2.ECM data upload

1) Upload the following data from the old ECM to the scan tool.

Injector ID Code

Vehicle speed correction data

3.Injector ID code upload

1) Connect the OBD2 scan tool to the DLC.

2) Turn ON the ignition switch.

3) Select the scan tool item.

Diagnostics > Engine > 4JJ3 > Programming > Injector ID Code > Upload Injector ID

4) Follow the directions on the screen and upload the injector ID codes to a scan tool.

4.Vehicle speed correction data upload

1) Turn ON the ignition switch.

2) Select the scan tool item.

Diagnostics > Engine > 4JJ3 > Programming > Vehicle Speed Correction Data > Upload Vehicle Speed Correction Data

3) Upload the vehicle speed correction data to the scan tool by following the on-screen instructions.

4) After completing the upload, turn off the scan tool.

5) Turn OFF the ignition switch.